Project management

Counseling & Concept Development

CFM Schiller accompanies you from the very beginning of your projects and helps you create efficient solutions which meet your requirements. Experienced engineers and certified technicians counsel you without obligations. In close collaboration with you, we develop solutions for your nonstandard test rigs, the test rig work environment or necessary infrastructure.

Please feel free to contact us! We are looking forward to visiting you onsite

Development & Design

Detailed design and development processes are the foundation for all of our standard and customer-specific products. CFM Schiller has specialized in customized solutions and optimized the development process to solve any occurring challenges. Every design is analyzed with the finite elements method regarding tensions and natural frequency of the components. This ensures state of the art products that fully meet your requirements. Our experienced engineers as well as engineering expertise since 1978 guarantee you products of highest quality with long life cycles.

CFM Schiller offers premium quality products at reasonable costs.

Project Assistance

CFM Engineers support your execution of the project. We participate at project meetings in your company and coordinate the workflow through time scheduling and regular benchmarking. If other companies are involved in the test rig development, we take charge of the communication between all project partners.

CFM Engineers realize your projects worldwide.

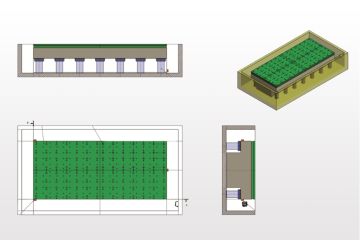

CONSTRUCTION EXECUTION & SUPERVISION

We accompany you worldwide before and during the construction phase to ensure the proper construction of your seismic mass according to our mutual specifications. The employees of CFM Schiller are cooperating closely with the construction firm. We take care of the timely execution of a project that is extraordinary to most construction firms.

The pit and the seismic mass are constructed by a local construction firm according to the formwork and reinforcement drawings from CFM Schiller.

Our special anchorage system is integrated into the existing reinforcement by experienced CFM Mechanics. Only after thorough measurement and approval, concrete is poured into the formwork.

Curing time for the concrete foundation is approx. 28 days. Not till then, our employees install special anchors and position the clamping plate on the seismic mass. After being adjusted, the clamping plate is grouted with special non-shrink cement grout.

At the end of the construction process, the air springs for the vibration isolation are installed. Further necessary assembly works and electrical installations are also carried out by CFM Schiller. As the last step, the vibration isolation system is commissioned.

ON-SITE ASSEMBLY

To fulfill our corporate philosophy "Everything from one source", every machine or machine system is pre-assembled at CFM Schiller before delivery to the customer. Final assembly and start-up at your location will be carried out by qualified and experienced CFM Mechanics worldwide.

Our assembly teams are trained for the tasks on complex machine assembly – specifically on custom-made machines and systems. The CFM Employees specialize in construction and assembly of vibration isolation systems, clamping plates, test rigs, and test rig components.

CFM Schiller offers mounting of hydraulic and pneumatic components as well as the electrical installations belonging to your machine or plant. Due to our extensive equipment and experience, particularly for hydraulic installations, CFM Schiller can provide start-up and test runs of your machine or plant before delivery.

If desired, we supply a certification of final inspection through our internal quality management.