Test rig & Machines

CFM Schiller offers you air springs, steel spring isolators, and elastomer elements of various types, in different sizes, and with customized specifications.

Whether you are looking to implement vibration isolation for an air conditioning system, a measuring table, a machine tool, or a full vehicle test rig – CFM Schiller provides the optimal solution for you. We gladly assist you with the layout of your vibration isolation and offer you our decades of experience. Both air springs and steel spring isolators are developed, manufactured, and tested in-house. Our range of products and services is completed with our installation service. Our assembly teams install the entire vibration isolation system for you – worldwide.

Design of Vibration-Isolated Supports

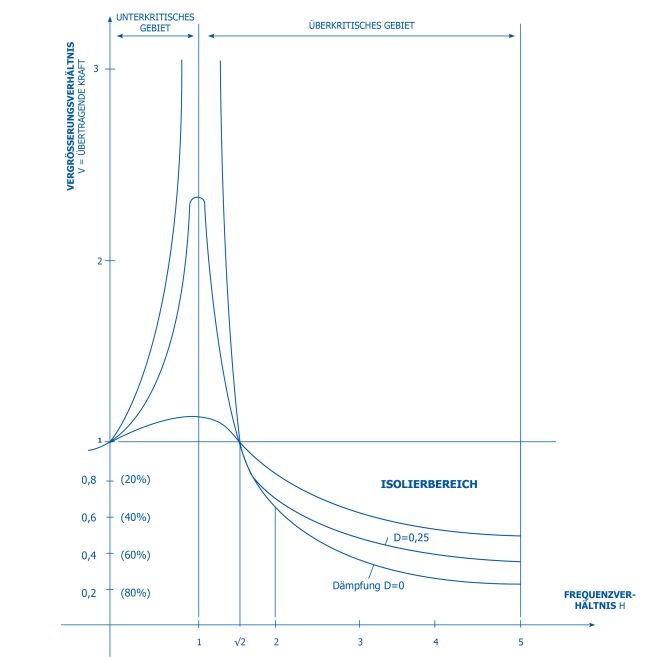

Periodiacally-excited oscillations

The performance of the vibration isolation significantly depends on the ratio η between the excitation frequency of the disturbance source and the natural frequency of the isolator. The isolator’s damping properties are an important factor as well. The lower the natural frequency of the isolator, the better is the degree of efficiency of the vibration isolation. The diagrammed amplification function shows that successful vibration isolation demands a frequency ratio greater than √2. If the ratio lies below this threshold value, critical resonances regarding the excitation forces will occur. In order to achieve an optimal efficiency of the isolation system, a value between 3 and 4 is generally chosen in practice.

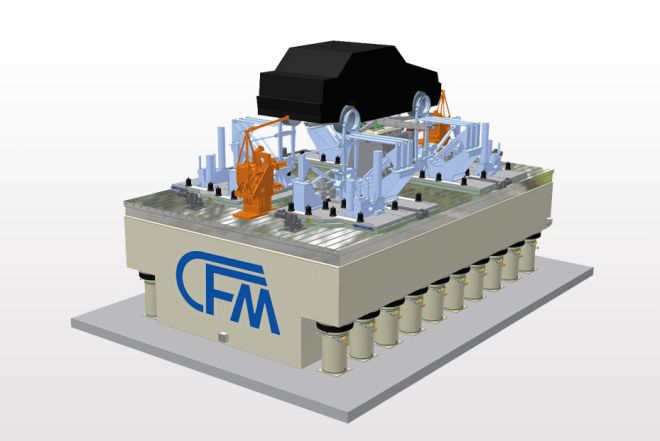

Vibration-Isolated Support of Test Rigs

Test rigs require a vibration-isolated support on air springs if any of the following cases occur: high dynamics, variable superstructures causing different centers of mass, or different excitation frequencies from the test rig. Effective vibration isolations should be applied if excitation frequencies greater than 3-4 Hz occur. Vibration isolations are urgently required even below 3 Hz if the application of the test rig causes high inertial forces due to large masses being in motion.

Examples:

- Full vehicle test rigs

- Road simulators

- Dynamic axle test rigs

- Multi-axial shaker tables

Vibration-Isolated Support of Machines

If machines constantly operate under identical conditions, i.e. no significant change of loads, centers of mass, or excitation frequencies, vibration isolation can be realized by means of steel spring isolators.

Examples:

- Lathes

- Grinding machines

- Presses

- Coal pulverizers

- Turbine supports

- Centrifugal casting machines

With very high dynamics (motion) of the entire machine or entire test rig, air springs or steel spring isolators with integrated viscous damping are applied. The viscous dampers absorb the motion by converting the kinetic energy into thermal energy.

The carrying structure of the sieving machine is effectively preserved from shock forces when supported on air springs. Due to better isolation, the steel framework and structure parts such as trays, slides, or guard rails are far less excited to vibrate. Thus, the drive motor of the sieving machine can save this amount of energy.

Examples:

- Crushing plants

- Cutting machines

- Mills

- Sieving machine