SAFETY TECHNOLOGY

Protective Systems - CFM Schiller offers protection concepts designed for your test rig.

During operation, access to the testing facility is generally restricted by means of security mechanisms. The possibility for visual or acoustic monitoring of the testing procedure is therefore impossible or very limited.

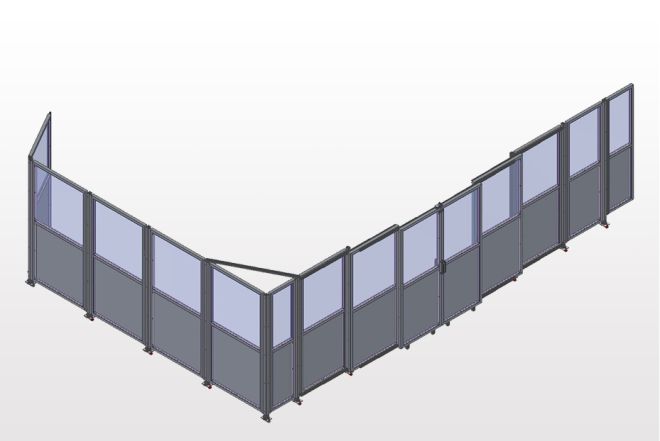

Modular Safety Fence

The safety fence from CFM Schiller effectively shields your test rig and protects individuals from flying components that could break loose in case of failure. At the same time, the safety fence allows nearly unobstructed view of the test rig while being outside the hazard zone.

The CFM Safety Fence is composed of modular fence elements and its layout is based on the existent clamping field. If structural changes are made to the test rig, an existent safety fence can be expanded or rearranged modularly. When the test rig is not operating, sliding doors provide access to the test rig for personnel and industrial trucks such as fork lifts. Limit switches on the sliding doors serve as a safety mechanism and can be integrated into the test rig’s control system.

Protective systems from CFM Schiller comply with the requirements stipulated in the German Occupational Safety and Health Act (Arbeitsschutzgesetz) and the European Union Directives 2009/104/EC and 2006/42/EC.

The modular safety fence from CFM Schiller has a standard height of 2 100 mm (approx. 6’ 10.6”). The standard width of each element is 1 000 mm (approx. 3.28’) and therefore suitable for T-slot distances of 200 mm and 250 mm. Elements with alternative height and width can be offered flexibly due to our in-house production of the entire safety fence system.

Mounting of the CFM Safety Fence on the clamping field is realized with T-slot nuts. This does not require any additional holes and does not damage the clamping plate. This clamping method also allows an easy, modular adaption or rearrangement of the safety fence if structural changes are made to the test rig. Relative motions at the gap between a seismic mass and the fixed floor can be compensated with special fence elements.

Single or double telescopic sliding doors provide access to the test rig. The entire passage has no obstructing contours so that industrial trucks can easily operate with maximum clearance. The sliding doors feature precision linear guides, which ensure easy opening and closing as well as the necessary stability for a large passage width.

Limit switches for supervision of the door position can be installed at customer’s option. These switches can be integrated into the master control system to shut down the test rig in case of trespassing during operation. This safety measure allows general access to the testing facility outside of the safety fence, making visual monitoring of the test rig possible.

Design of the CFM Safety Fence

The safety fence is composed of columns and fence elements. All components are painted according to the customer. The fence elements feature elastically mounted polycarbonate sheets (Makrolon) in the upper half. This transparent plastic material is for example used for aircraft windows due to its excellent impact strength and bursting resistance properties. The elastic mounting reduces residual stresses in the Makrolon sheets, increasing the impact energy that can be absorbed. The lower half is covered with sheets. Polycarbonat sheets can be installed upon request. The interfaces between the columns and fence elements have gaps, which are closed with covering sheets for maximum safety.