ELASTOMER TEST RIGS

Due to continuously increasing requirements to loadings during operation, service life, system reliability, and diversity of applications, the testing requirements for elastomer supports are under continuous change. Testing, which simulates the physical conditions of complex elastomer supports during operation, constantly gains importance.

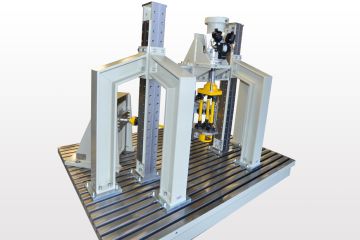

3-axial Elastomer Test Rig

The test rig setup for the 3-axial, orthogonal application of load is composed of components from our modular MOCOKIT® system. This system offers a high degree of flexibility and robustness. Deliberate usage of the modular construction kit allows very quick realization of additions, changes, and extensions to the setup according to customer preferences.

The modular system also increases testing capacity and flexibility for component part testing significantly. The test rig provides excellent accessibility to the specimen as wells as options for quick and easy installation of all needed measuring instruments. Additionally, the spacious working area around the specimen can be used to place necessary devices for testing.

The vertical actuator is mounted on the cross beam of the MOCOKIT® portal load frame. Two reaction brackets with height adjustment are mounted on the clamping plate adapting the two actuators for horizontal forces in X and Y direction. A special adapter serves both to attach the specimen and to apply the forces orthogonally via coupling bars and adjustable ball joints without backlash.

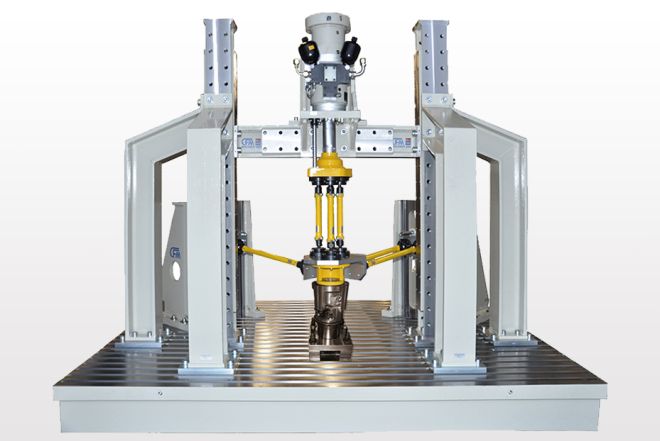

4-axial Elastomer Test Rig

The 4-axial elastomer test rig from CFM Schiller features an additional rotary degree of freedom about the vertical axis. Design and functionality are basically analogous to the 3-axial version. The respective adapter, which transmits the forces to the specimen, holds a connector for an additional fourth actuator. This actuator applies the moment about the Z axis via coupling bar and ball joint.