ALUMINIUM SHAKER TABLES

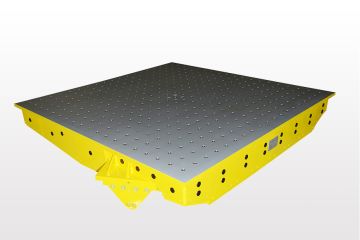

Uniaxial and multiaxial shaker tables in light-weight design are applied in test rigs that examine dynamic material and component properties of single parts and assemblies. They are also used for driving simulators, comfort testing in prototyping, and earth quake simulations.

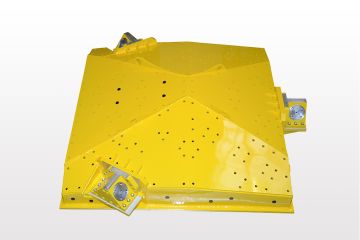

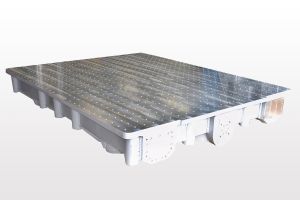

These so called simulation tables or systems are complex test rigs with motion in up to 6 degrees of freedom. Their performance significantly depends on the quality of the shaker table. CFM Schiller develops aluminium shaker tables that are unique throughout the world in cooperation with renowned test rig manufacturers. Our products are optimized in terms of natural frequency, stiffness, light-weight potential, modularity, and long service life. Besides our established standard tables, we offer customized designs for your special applications.

The iterative layout process is based on FEM calculations. CFM Schiller not only specializes in design, but also in manufacture of these complex aluminium weldments with machined surfaces. Shaker tables with dimensions of 6 000 x 6 000 mm (19.68‘ x 19.68‘) are possible.

The natural frequencies of each aluminium shaker table are far above the frequency band in which the test rig is operated. The 6-axial aluminium shaker tables for hexapods in particular feature very high natural frequencies above 300 Hz due to their optimized core structure.

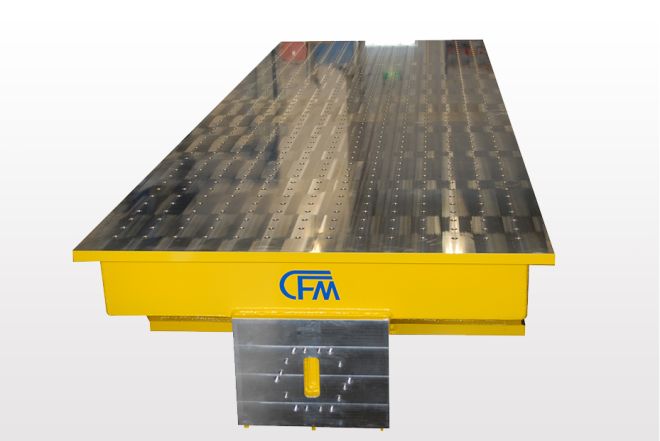

Seismic Shaker Tables

Special applications for aluminium shaker tables from CFM Schiller are test rigs for earth quake simulation. These shaker tables generally have one or two degrees of freedom, realized with linear guides. For seismic testing of very large structures or even entire houses, shaker tables with dimensions of 6 000 x 6 000 mm (19.68‘ x 19.68‘) are provided.

Image: 1-axial aluminium shaker table 6 000 x 6 000 mm for earth quake simulations

The hydraulic or electric actuator units of the simulation system as well as its control are provided by the customer or third parties. CFM Schiller delivers the following test rig components:

- Shaker table body

- Reaction brackets for actuators

- Bell cranks

- Coupling bars

- Ball joints

- Knuckle joints

Design:

- 1-axial version with linear guide units

- 2-axial version with linear guide units and cross slide

- 3-axial version with actuators and coupling bars

- 6-axial version as hexapod or in orthogonal design

Anwendungen:

- Fatigue testing of components and subassemblies

- Materials testing

- Noise, Vibration, and Harshness (NVH)

- Buzz, Squeak, and Rattle (BSR)

- Driving simulations

- Comfort testing Earth quake test rigs