Agricultural Machinery Test Rigs

Testing systems for towed and mounted agricultural implements, various test rigs for agricultural machinery and their protective structures (ROPS, TOPS, FOPS) as well as turnkey plant construction planning for modern development laboratories are offered b

We have specialized in providing customized system solutions for the increasing requirements in the agricultural industry. Besides development, manufacture, and installation of the test rig, CFM Schiller carries out project management for construction as well as certified commissioning of the plant if desired. Feel free to contact us with your specifications for a non-binding quotation.

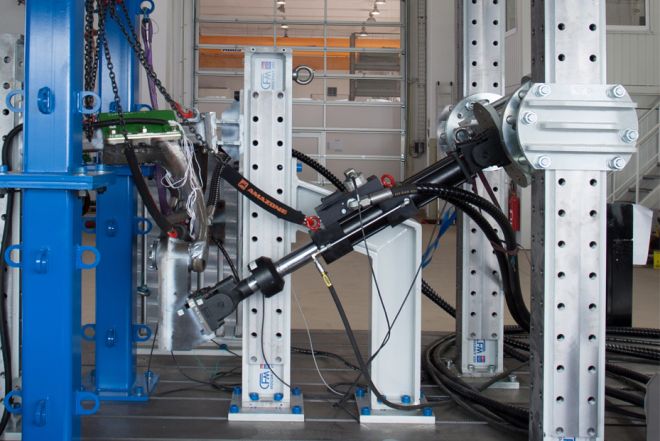

Tillage Machinery Test Rig

Test setup

The framework is composed of MOCOKIT® 250 components from the CFM Schiller modular construction kit. The interfaces between specimen and actuators are realized with customized adapters. Alternatively, components from our MOCOKIT® system such as coupling bars and ball joints can be used as interfaces.

Application of force

Loads are applied by means of two servo-hydraulic actuators provided by the customer. One actuator applies the force Fx in X direction. The other one applies the net force of Fy and Fz on the specimen. Both actuators apply pulsating loading in cycles with different amplitudes. In case of fatigue failure, a specially developed modular frame system is used as safety equipment. It protects both the specimen and the actuators against falling.

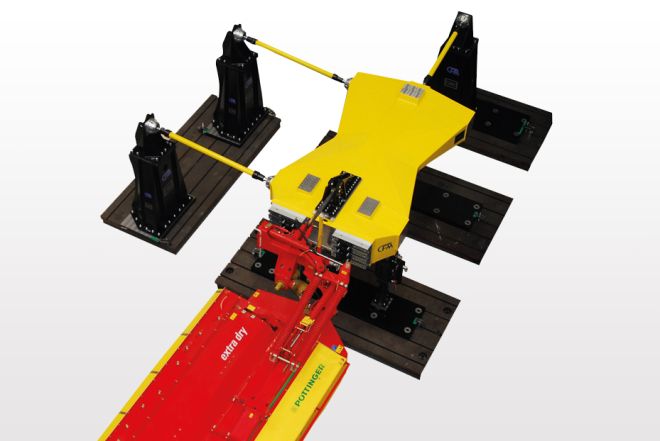

Test Rig for Three-Point Hitch Implements – 3-Channel

This testing system has been developed and manufactured to analyze the fatigue durability of agricultural implements, such as plows, harrows, cultivators, and similar soil cultivation implements.

The basic configuration of the test rig allows motion with 3 degrees of freedom. An optional extended version offers 6 degrees of freedom. The necessary mechanical adapter flanges for the extension are already integrated in the basic configuration of the loading frame.

The test rig basically consists of a symmetrical loading frame, which is a high-strength aluminium weldment optimized regarding stiffness. The loading frame performs the desired motion through servo-hydraulic drive units. Connections between the drive units and the loading frame are realized with coupling bars.

The test rig is installed on several T-slotted steel plates, which are mounted on the foundation of the testing facility.

The test rig is designed to hold agricultural implements with hitch size categories 3, 4L, and 4H. It can be extended modularly for all further hitch size categories. For this purpose, the adapter for the upper link and the T-slotted adapter flanges for the lower hitch points can be equipped universally. The design can be customized according to customer specifications.

Test Rig for Three-Point Hitch Implements – 1-Channel

This testing system has been developed and manufactured to analyze the fatigue durability of agricultural implements, such as plows, harrows, cultivators, and similar soil cultivation implement.

The basic configuration of the test rig allows motion with 1 degree of freedom. An optional extended version offers 6 degrees of freedom. The necessary mechanical adapter flanges for the extension are already integrated in the basic configuration of the loading frame.

The test rig basically consists of a symmetrical loading frame, which is a high-strength aluminium weldment optimized regarding stiffness. The loading frame performs the desired rotational motion through a coupling bar with servo-hydraulic drive unit.

Furthermore, the test rig comprises a base framework made of steel with two plummer block bearings to support the loading frame. A clamping field with T-slots is used for mounting of all test rig components.

The test rig is designed to hold agricultural implements with hitch size categories 2, 3, and 3N. It can be extended modularly for all further hitch size categories. For this purpose, the adapter for the upper link and the T-slotted adapter flanges for the lower hitch points can be equipped universally. The design can be customized according to customer specifications.

Spray Boom Test Rig

CFM Schiller has developed and manufactured this testing system to analyze the fatigue durability of spray booms used in agricultural fertilizing or pest control. The test rig is designed to mount spray booms with a maximum weight of 4 000 kg (8 818 lb). The test rig consists of a specially developed, anodized aluminium table to adapt the spray boom structure. The aluminium table performs the desired motion through servo-hydraulic drive units, which are connected with coupling bars.

The test rig is installed on four base plates, which are anchored in the concrete foundation. Since the test rig can be installed and operated both outside and inside, all relevant components have been specially designed and manufactured in a corrosion-resistant way.