Clamping Plates

CFM Schiller develops, manufactures, and mounts clamping plates made of cast iron, steel, stainless steel, or in a hybrid design from steel or stainless steel and polymer concrete. According to the customer-specific application and the technical requirements, our engineers select the right product for your needs.

Clamping plates from CFM Schiller allow adaption, positioning, and clamping of all components required in the test setup. Plates are made from the basic materials gray cast iron, steel, and stainless steel. They come in a solid version or in a hollow version with rib structure. Both versions are anchored and grouted on foundations in a dynamically fatigue rated way. Solid clamping plates can also be mounted directly on spring elements. The hybrid design, which basically is a hollow body entirely filled with polymer concrete, is also supported directly on spring elements.

The upper side of the clamping plate is generally machined with T-slots according to DIN 650. These can run in longitudinal, transversal, or both directions at customer’s option. Alternatively, the upper side can be manufactured with a hole pattern or a customized combination of holes and T-slots.

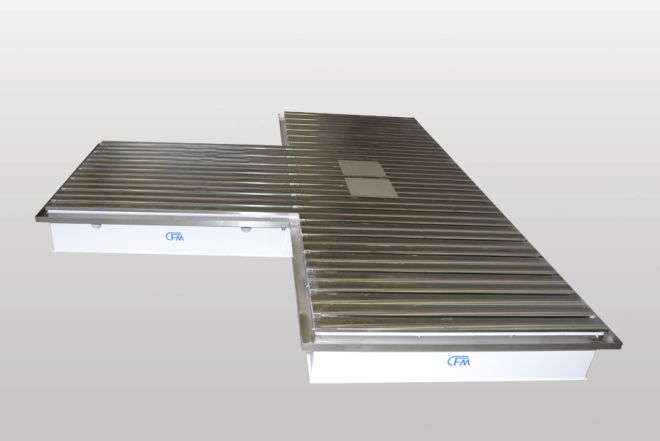

CFM Schiller offers customized solutions for your requirements regarding shape and size. Maximum dimension and weights differ for different plate types due to manufacturing processes. To enlarge the working space, multiple single plates can be assembled to a clamping field. This works for all types of clamping plates. The connection is realized with high-strength screw joints.

When leakage of oil is expected, an oil retention system is offered for reasons of environmental protection. The sensors are certified according to the German Federal Water Act (WHG). Among other things, it comprises a circumferential oil channel and an oil reservoir for larger leakage amounts. Grouting and adjustment holes used for mounting procedures on a foundation can be oilproof for all types of plates. Furthermore, all joints between clamping plates on a clamping field can be sealed against oil.

The CFM Engineers gladly assist you with the selection of the right clamping plate. FEM analyses are applied during the layout process for your specific application. Feel free to contact us with detailed specifications for a non-binding quotation.

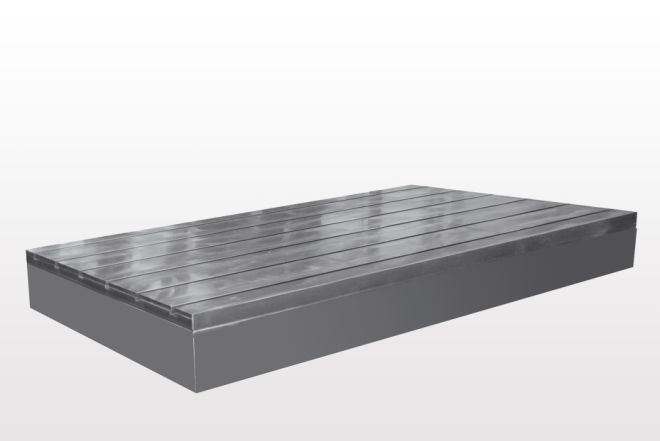

Steel Clamping Plates

Clamping plates made of steel are ideally suited for high loadings due to the higher Young’s modulus of steel compared to cast iron. Besides solid plates, steel clamping plates are offered as ribbed weldments. The rib structure allows to sustain high bending and torsion forces. An optional bottom plate closes the clamping plate and additionally increases its stiffness. Maximum dimensions for a single plate are 9 000 x 3 000 x 800 mm (approx. 29.52’ x 9.84’ x 2.62’).

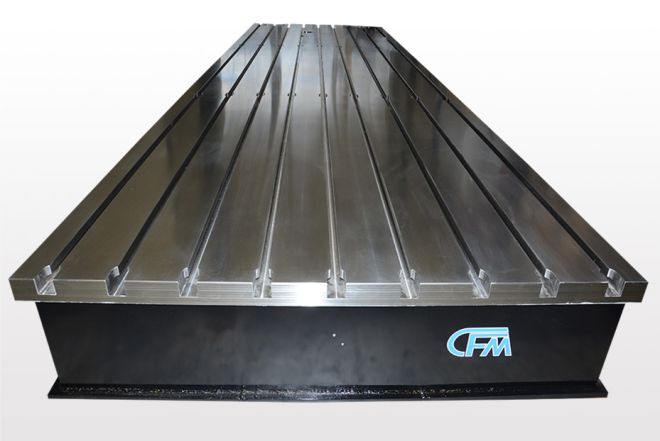

Cast Iron Clamping Plates

Clamping plates made of cast iron are the economic standard solution for applications with regular loadings. Gray cast iron EN-GJL-250 (0.6025) has good damping properties and high accuracy as all functional surfaces are machined. The clamping plates are casted free of residual stress and are relatively immune to corrosion. Single plates can be produced with a maximum weight of 25 tons

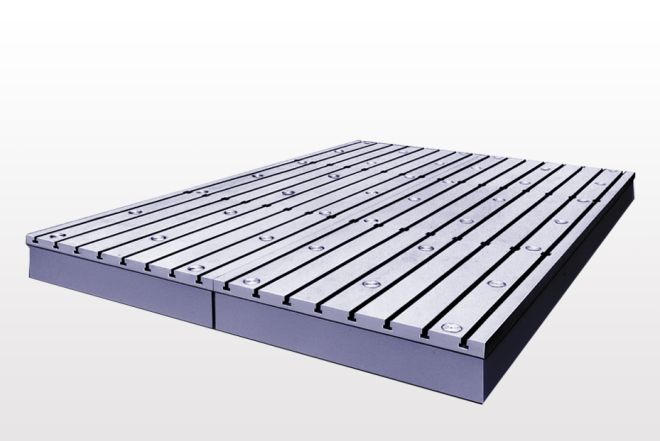

Stainless Steel Clamping Plates

Clamping plates made of stainless steel feature excellent corrosion resistance. They are generally applied in wet, moist, and other corrosive environments. Analogous to steel clamping plates, they come in solid and ribbed versions. The rib structure and bottom plate provide very good bending and torsional stiffness properties. Maximum dimensions for a single plate are also 9 000 x 3 000 x 800 mm (approx. 29.52’ x 9.84’ x 2.62’).

Hybrid Design Clamping Plates - CFM Hybridur

Clamping plates in hybrid design are particularly suitable to setup engine, transmission, and powertrain test rigs. Especially in the field of e-mobility, testing of electric motors and their components is carried out with high rotational speeds. The occurring high-frequency oscillations are effectively reduced by the hybrid structure with its very good damping properties.

The hollow body of the hybrid plate is designed as steel or stainless steel weldment, depending on the application. It is filled with a high-strength, highly damping polymer concrete.

Maximum dimensions of the hybrid design clamping plate are based on the restricting maximum manufacturing weight of 40 tons.